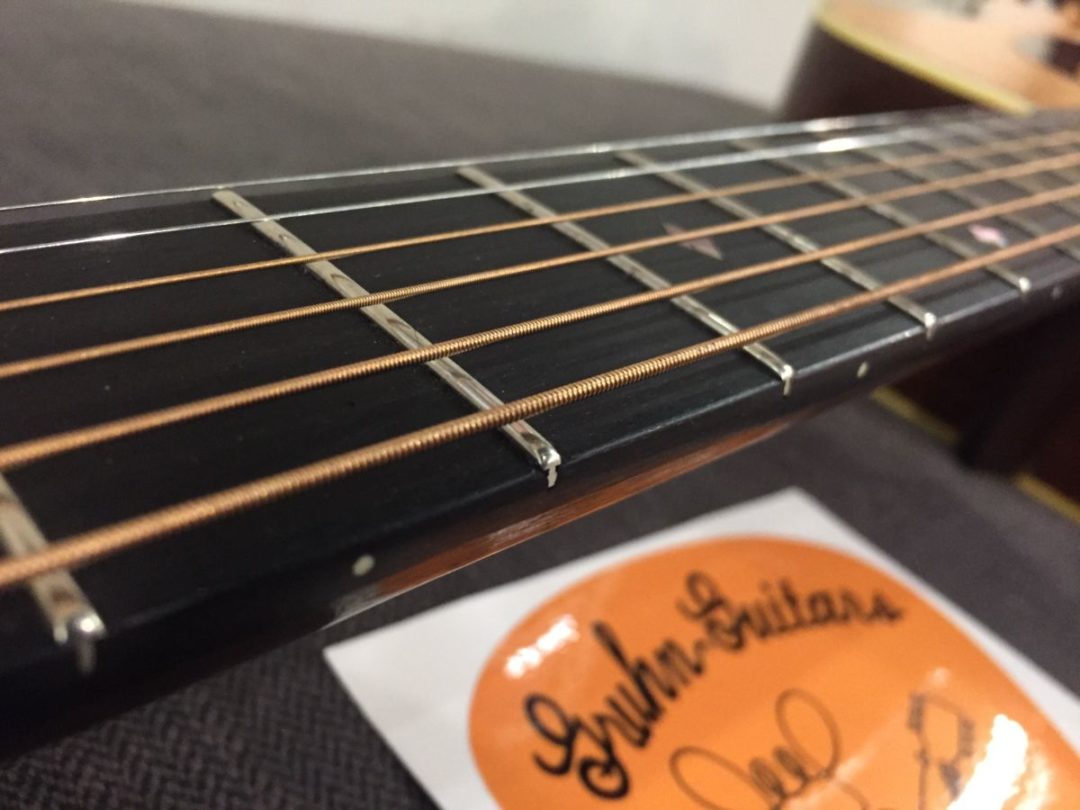

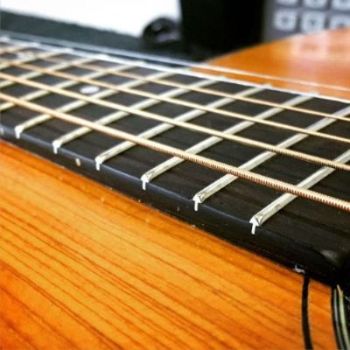

One of the first build or repair traits to catch my eye on any steel-stringed instrument is fretwork. Fretwork allows an instrument to look and feel great when it’s played — but it also can make an instrument unplayable if it’s not carried out properly.

Common Fret Problems and How to Fix Them

Once the fingerboard is prepped properly with respect to its radius, flex-points and truss-rod function, the frets are then installed. The frets can then be glued and the excess material is removed with fret cutters. The ends will then be beveled and the newly installed frets will receive the lightest fret-dress to ensure perfect playability.

Step-by-Step Guide to Fret Leveling and Crown Shaping

Within the polishing process I like to stop at 1,000-grit sandpaper to lightly manicure either side of each fret using a fret-end file. The strokes need to be uniform throughout the board — then the polishing process continues with 1,500, 2,000 and super-fine-grade steel wool. Executed in this way, the frets have a look of mindfulness with the finesse of experience.

— Greg Voros

(Greg Voros is the repair shop manager at Gruhn Guitars in Nashville.)