(Dave Johnson is an instructor at Guitar Craft Academy Nashville and the owner of Scale Model Guitars in Nashville.)

I’m currently working on a restoration of a 1931 Martin OM-18 for Carter Vintage Guitars in Nashville. This job will include a neck reset, something that sounds scary, but isn’t a difficult repair if you adhere to time-tested techniques and procedures.

Tips for Restoring Vintage Guitars

The most risky part of the neck reset is releasing the dovetail from the neck block. There is really only one rule to adhere to when pulling the neck out of a vintage guitar, and I can sum it up in five words: Do not break the heel.

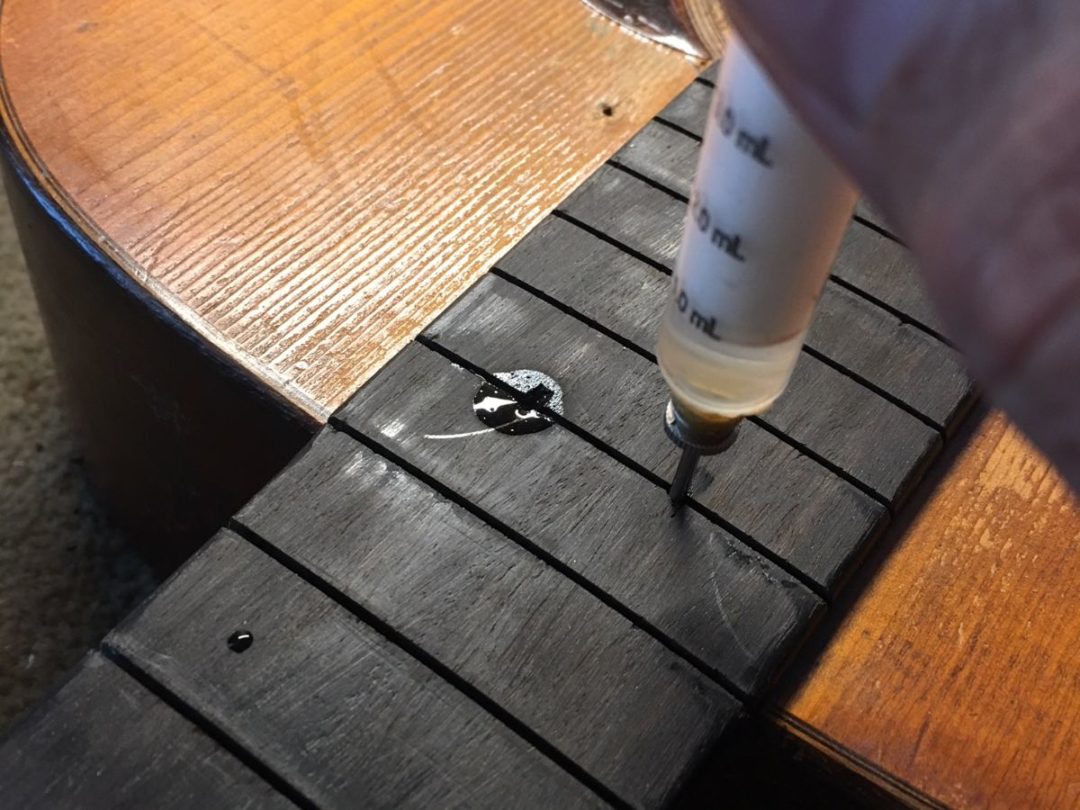

I start by bringing water to a boil in a hot pot and then injecting it into the holes that I drilled down the neck pocket with a syringe. This is really just to get it started — the hot water will instantly release the exposed areas of hide glue inside the pocket and get things moving.

You don’t want to overdo it with the syringe and hot water. We don’t want to turn the dovetail and neck pocket into a sponge, we’re just trying to release the big stuff. After a few passes, things will start to move.

After I can lightly move the neck around in the pocket, that’s when I know I am ready for steam. For this demo, I actually made a new jig out of MDF and cork board, which you can see on my Instagram feed covering the entire restoration process. This fixture presses the body down onto a block that contacts only the bottom of the heel and applies downward pressure by two threaded clamps. The steam is made by an espresso maker with a tube and needle attached. It only takes 3 or 4 quick blasts of steam and the neck jumps right out.

If you try the steaming method, just keep in mind that you want to blow steam out of the needle, not bursts of water. Also, the less steam the better, since it can blush and damage the finish. This neck came out nice and clean!

Handle the Neck Carefully

I want to point out something very important here. Almost every neck that you pull out will have a pocket of glue at the bottom from when it was made. This is a result of building process (excess glue has to go somewhere, usually down). They may also have factory dovetail shims. Factory shims and pockets of glue at the bottom are what will hold half of the neck and break your heel. Take your time and be very careful not to force the neck — let the steam and jig do the work for you.